Epoxy compounds for potting and encapsulation

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation.

Epoxy potting compounds are designed to work in temperatures of less than 180 degrees and offer the highest mechanical strength. Our range of applications includes protection from acids, alkalis, gasoline and solvents.

At Veeyor Polymers, we have special compounding techniques that allow the use of halogen-free and ROHS compliant pre-polymers to achieve UL94 V-0 flame retardancy properties.

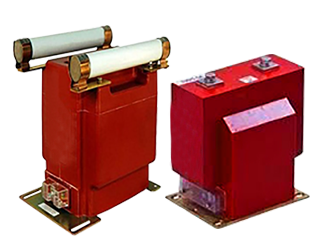

Transformers are exposed to hot temperatures and high voltage. To function properly, they need component protection. Veeyor polymers manufacture a full line of formulated epoxy resin used in transformers and transformer components

VEEFILL 303 F / H 151 system is a cold curing epoxy system, that is mainly used in upto 11 kV CT / PT applications.

Key Features

- Easy to use 2 component system

- Anti-settling properties

- Class B insulation

Technical Data

| RESIN / HARDNER PROPERTY | UNIT | SPECIFICATION |

|---|---|---|

| Resin Viscosity | cps @ 25°C | 9000 – 17000 |

| Resin Density | g / cc @ 25°C | 1.4 – 1.8 |

| Hardener Viscosity | cps @ 25°C | 25 – 45 |

| Hardener Density | g / cc @ 25°C | 0.97 – 0.99 |

Built for superior performance, Veeyor’s epoxy potting compounds are formulated to resist heat and water, and to eliminate rusting and eventual system breakdown of PCB components. VEEFILL 401 F / H 105 F system is a hot or latent curing epoxy system. It is mainly used to encapsulate in High voltage CT / PT and bushings

Key Feature

- Easy to use 2 component system

- Anti-settling properties

- Class F insulation

- Ready to use in pressure gelation systems

Technical Data

| RESIN / HARDNER PROPERTY | UNIT | SPECIFICATION |

|---|---|---|

| Resin Viscosity | cps @ 25°C | 10000 – 30000 |

| Resin Density | g / cc @ 25°C | 1.4 – 1.9 |

| Hardener Viscosity | cps @ 25°C | 7500 – 30000 |

| Hardener Density | g / cc @ 25°C | 1.4 – 1.9 |

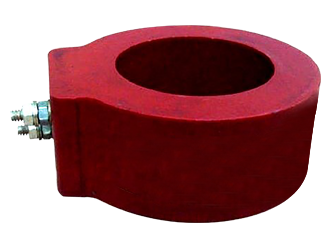

The role of the magnetic core in transformers is often stated as being to increase and concentrate the magnetic flux that links the primary and secondary coils. Veeyor’s impregnation compounds feature long-term storage stability, exceptional chemical/moisture resistance and the ability to withstand elevated temperatures.

VEEFILL 3001 system is a hot or latent curing epoxy system, it is mainly used to encapsulate in High voltage CT / PT and bushings and magnet re-winding.

Key Features

- Anti-settling properties

- Class H insulation

- Ready to use in pressure gelation systems

Technical Data

| RESIN / HARDNER PROPERTY | UNIT | SPECIFICATION |

|---|---|---|

| Resin Viscosity | cps @ 25°C | 10000 – 50000 |

| Resin Density | g / cc @ 25°C | 1.4 – 1.9 |

| Hardener Viscosity | cps @ 25°C | 7500 – 30000 |

| Hardener Density | g / cc @ 25°C | 1.4 – 1.9 |

Outdoor Current transformer and its components need to withstand open-air environmental conditions and are exposed to humidity, water, inspects and reptiles and elevated heat. Veeyor’s VEEFILL 323 F SP is hot or latent curing cycloaliphatic epoxy resins that provide superior strength to withstand outdoor conditions. It offers superior arc track, ozone, and ultraviolet-resistive properties while maintaining physical strength. It is mainly used to encapsulate in High voltage outdoor CT / PT and bushings

Key Features

- Anti-settling properties

- Class F insulation

- Outdoor application

- Cycloaliphatic resin

Technical Data

| RESIN / HARDNER PROPERTY | UNIT | SPECIFICATION |

|---|---|---|

| Resin Viscosity | cps @ 25°C | 20000 – 50000 |

| Resin Density | g / cc @ 25°C | 1.4 – 1.9 |

| Hardener Viscosity | cps @ 25°C | 7500 – 30000 |

| Hardener Density | g / cc @ 25°C | 1.4 – 1.9 |

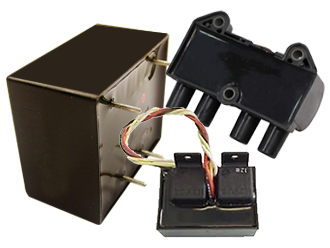

Filling an electronic assembly with an epoxy potting compound can be challenging Especially, selecting the wrong epoxy mixture can lead to a dangerous exothermic reaction. An exothermic reaction can produce enough heat to damage the components that the epoxy was intended to protect. Excess shrinkage can create stress on components or create cracks in the epoxy when cured. VEEFILL 303 F / H 160 system is a cold curing epoxy system, it is mainly used in electronic potting applications where low exotherm in required

Key Features

- Anti-settling properties

- Class B insulation

- Low exothermic reaction

- Long potlife and superior performance

Technical Data

| RESIN / HARDNER PROPERTY | UNIT | SPECIFICATION |

|---|---|---|

| Resin Viscosity | cps @ 25°C | 9000 – 15000 |

| Resin Density | g / cc @ 25°C | 1.4 – 1.8 |

| Hardener Viscosity | cps @ 25°C | 300 – 700 |

| Hardener Density | g / cc @ 25°C | 0.97 |

VEEFILL 60 / H 151 system is a general-purpose cold curing epoxy system. It is mainly used in electronic potting, filter sealing, magnet re-winding, sensor potting applications

Key Features

- Anti-settling properties

- Class F insulation

- Medium viscosity

Technical Data

| RESIN / HARDNER PROPERTY | UNIT | SPECIFICATION |

|---|---|---|

| Resin Viscosity | cps @ 25°C | 3000 – 10000 |

| Resin Density | g / cc @ 25°C | 1.4 – 1.7 |

| Hardener Viscosity | cps @ 25°C | 25 – 45 |

| Hardener Density | g / cc @ 25°C | 0.97 – 0.99 |